The Basics of Landscaping

Landscapes add beauty and value to properties, make outdoor spaces functional, and are good for the environment. To achieve a great-looking, well-designed landscape, it’s important to understand the basics of landscaping.

The key principles are proportion, pacing, and unity. They create a harmonious relationship between house and garden. They also emphasize the importance of a permeable hardscape to reduce water runoff and evaporation. Visit https://www.jupiterlandscaping.net/ to learn more.

One of the best ways to bring interest to your landscape is with planting beds. These can be in the form of flower beds, vegetable gardens or shrubbery areas. They are the foundation of your landscape and can help you achieve the look you desire in your outdoor living space. When designing and constructing a planting bed, there are many factors to consider such as size, color, structure, and maintenance needs.

When creating a new garden bed it is important to check with your local government for any buried utility lines that may be located on or near your property. This will prevent costly mistakes that could be made if the lines are accidentally cut or damaged during the creation of the planting bed. The traditional method of establishing a bed is to dig up the existing sod or turfgrass, loosen the soil and add organic matter and limestone along with recommended fertilizer rates. This tried and true method has worked well for generations of gardeners.

It is always a good idea to test the soil in your planting bed to determine its nutrient levels. This will give you a better idea as to what steps to take in preparing the bed for the desired plants. If the soil is sandy, for example, it would be beneficial to incorporate some organic matter into the bed as this will aid in improving its texture.

A bed that already contains perennials, bulbs and/or shrubs will require a bit more care. It is important to be careful not to disturb their root systems and to continue to monitor the condition of the soil. A layer of mulch will help keep weeds down and will also assist in preserving moisture.

A great idea to try in this type of bed is to add ground cover plants such as periwinkle, creeping phlox or sedum. These will not only add color, but they will also reduce the amount of time that you need to spend pulling weeds. The best time to plant these types of ground covers is in the fall when they can be tucked under existing weeds or under newly established shrubs and perennials.

Lawns

Lawns are the quintessential symbol of the American landscape, and a well-manicured lawn can add tremendous curb appeal to your property. However, this cultural norm is masking a less talked about reality: the environmental damage that accompanies traditional grass lawns. A shift away from the classic American lawn toward a native plant landscape is not only more environmentally sustainable, but it can also be as visually appealing as a manicured green grass lawn.

Lawns often require significant amounts of water to maintain their lush, green appearance. The irrigation needed to keep them healthy can put a strain on local water resources, which is detrimental to the environment. In contrast, native landscapes are often drought tolerant, reducing the need for constant irrigation.

While lawns provide many benefits, they can also be host to a variety of pests and diseases. One of the most common lawn diseases is fungal infection, which can be exacerbated by water stress, improper mowing and soil conditions. In addition, lawns can be an ideal environment for invasive species to take root and displace natural ecosystems.

However, the good news is that a healthy lawn, utilizing preventative care strategies including soil testing and analysis, balanced fertilization, aeration and irrigation, and proper mowing techniques can be more resistant to disease, insects, and weeds. In fact, a healthy lawn can actually support biodiversity by encouraging natural predators of invasive plants, such as earthworms and beetles that prey on grubs.

Additionally, a healthy lawn can help to reduce noise pollution by acting as an insulator, absorbing and reducing the impact of footsteps, vehicles and other sounds. Moreover, a lawn can act as a filter to clean rainwater and runoff, protecting rivers and streams from debris and pollution.

Unfortunately, many homeowners are stuck in the mindset that native plants will look unkempt and unkempt compared to the lush green lawns they’re used to. This is a misconception that is driven by outdated HOA rules and other factors that discourage landscape changes. Rainscapes can help you rethink your landscape and make the switch to a native plant landscape, a move that is beneficial for the environment and reflects sound stewardship.

Water Features

Water features create a sense of tranquility and enhance a landscape’s aesthetic. They can be designed to complement any exterior design and can range from a simple fountain to a large pond or waterfall. Water elements can be incorporated into the landscape to add visual interest year-round and increase property value. They can also encourage wildlife and improve air quality.

The soothing sound of a water feature promotes relaxation and helps mask noise pollution from passing cars or neighbors’ conversations. Water features can also improve a backyard’s microclimate by reducing humidity and cooling the area. This is especially beneficial during summer months, when water can provide a refreshing retreat.

Adding a water feature to your garden can make it an attractive spot for visitors, creating a gathering space that will be enjoyed by friends and family. It can also act as a focal point for the landscape and create a stunning centerpiece that will be sure to impress guests. Whether it is an Asian-inspired water garden or a koi pond, a well-designed water feature will not only boost a yard’s curb appeal, but will help elevate the overall look of your home.

The calming effect of water is also beneficial to our health. Research shows that exposure to water reduces cortisol levels, lowers heart rate and blood pressure, and decreases anxiety and depression symptoms. The meditative nature of water’s presence in a landscape creates intimate sanctuaries that offer a reprieve from the stresses of daily life.

In addition to providing a peaceful setting, water features are an ideal environment for native aquatic plants and wildlife. They attract birds, butterflies, bees, and other insects to the garden and provide habitats for flora such as lotus, water lilies, cattails, and iris. This ecosystem is a key part of a healthy garden and contributes to ecological balance.

Lighting

With our mild evenings, landscape lighting extends the usability of outdoor living spaces well after dusk. It also adds to the visual appeal of your home by highlighting key design features and illuminating beautiful plant species in their natural color and texture.

When planning your lighting system, it’s important to keep in mind what your goals are for the space. Do you want to improve safety for nighttime gatherings, highlight a garden or water feature, or set the mood for relaxation? Each goal will influence the lighting options you choose.

Once you’ve established your goals, the next step is to assess the landscape and determine what areas need illumination. For example, a pathway may require path lights for safety, while a water feature might be better showcased with spotlights.

There are many different types of landscape lighting to consider, including uplighting, cross-lighting, and silhouetting. Uplighting creates dramatic shadow effects that draw attention to a focal point, such as a tree or statue. Cross-lighting eliminates shadows by lighting a feature from both sides. This technique is often used to highlight textured plants, such as saguaros and agaves.

Finally, silhouetting focuses light behind an object to highlight its shape and form. This effect is often used to enhance the beauty of a sculpture, accentuate a fountain’s movement, or highlight a tree’s unique structure.

Lastly, you’ll want to consider the style of your lighting fixtures and how they complement the overall design aesthetic of your home and landscape. For example, a contemporary landscape might look more polished with lighting that reflects modern design principles, while a traditional home would be enhanced with lights that reflect classic Mediterranean-style elements.

Creating a landscape that looks just as stunning at night as it does during the day takes skill and attention to detail. A professional landscape designer can help you achieve the right balance of functionality, beauty, and ambiance to make the most of your outdoor living spaces.

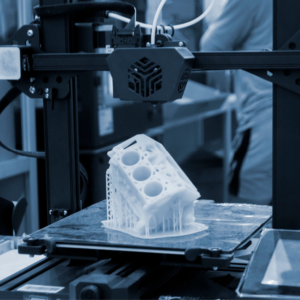

3D Printing Services

3D Printing Arizona is a fabrication technique that builds three-dimensional objects using layers of materials, like plastics, composites and bio-materials. Also known as additive manufacturing, this technology is making waves in the industry with revolutionary benefits for manufacturers.

Once the CAD model is created and “sliced” into thin cross-sections, the printer takes over. A nozzle deposits the material layer by layer until the object is complete.

A rapid prototype is a model that can help identify design flaws and improve a product before the final product is manufactured. It is also an effective way to test a product with a limited number of users and can help reduce the time and cost needed to make changes. The term is closely related to the concept of a minimum viable product (MVP) and many designers use both terms interchangeably.

The process of creating a physical prototype using 3D printing involves converting digital designs into tangible objects through layer-by-layer fabrication. The technology offers a wide range of materials to choose from, allowing for experimentation with different design features. For example, a designer can choose to use different shapes, colors and textures to see how these variables affect form and function.

3D printing is a quick and inexpensive method for producing a prototype, which can then be modified as necessary before the manufacturing process begins. This helps companies avoid the high costs and lengthy development time associated with traditional manufacturing methods, such as injection molding or casting metal.

During the prototyping phase, it is important to create prototypes that are as close to the final product as possible. Functional prototypes are often used to demonstrate and validate a product’s functions. Visual appearance is a secondary consideration when creating this type of prototype. Functional prototypes are often created in parallel to allow for testing of various components separately before they are incorporated into a more comprehensive version. This can help developers determine which functions are essential for a successful product.

There are several different 3D printers that can be used for prototyping, including fused deposition modeling (FDM), selective laser sintering (SLS) and stereolithography (SLA). Each has its own set of benefits and disadvantages for various applications. For example, FDM is a popular and user-friendly technology that uses thermoplastic filaments to build models from layer to layer. SLS and SLA utilize powdered material that is sintered or solidified through a laser. Both of these processes can be used to produce both plastic and metal prototypes.

Cost-Effective Manufacturing

With the manufacturing market shifting towards more personalized products and on-demand production, 3D printing finds a range of uses. 3D Printers can be used to produce prototypes, spare parts or finished products at a fraction of the cost associated with traditional manufacturing processes. The technology also helps reduce costs throughout the entire workflow, from design and product development to production and warehousing.

The most obvious benefit of 3D Printing is that it can be used to create a wide variety of complex, custom shapes without the cost and time involved in modifying existing tools or building new molds. This translates to shorter lead times and lower labor costs, which in turn can significantly decrease production and shipping costs.

One of the most significant cost savings comes from the fact that the printing process produces very little material waste. The printing method dispenses raw materials layer-by-layer, so only the amount that is needed is added to the final object. This makes it far more resource-efficient than subtractive manufacturing methods, which often generate large amounts of scrap material.

Another major source of cost reduction comes from the ability to make iterations of a prototype much more quickly and cheaply than with traditional methods. Since a 3D printed prototype is based on digital CAD data, it can be easily modified and reprinted to test different design options – and to correct mistakes. This can accelerate the product development phase, reducing overall cost and risk of costly errors.

3D printing can also be used to reduce the number of components in a product. This can save on labour costs during assembly, and it may cut down on maintenance costs. It can also make it easier to ensure that mating surfaces fit together correctly, reducing the potential for leaks or damage.

The printing process can also be used to produce parts that are extremely lightweight and strong. Using plastic materials like PETG and ABS, or high-performance carbon fibres, manufacturers can experiment with designs that would be very difficult to make with conventional methods. This enables them to create innovative products that are lighter and more durable than the competition, without having to sacrifice performance or price.

Lightweight and Stronger Parts

3D printing allows for the creation of lightweight and strong parts that can be used in a wide range of applications. Creating strong and durable parts requires careful consideration of the materials, printer settings, part orientation, and internal structure of the printed object.

The strength of a printed object depends on its mechanical properties, such as its tensile strength. This property is measured in megapascals, which is a unit of measurement equal to one million newtons of force per square meter. There are several different ways to increase the strength of a print, including tweaking the printer settings and applying post-processing techniques. Among the most effective methods is annealing, which involves heating the part to re-organize its molecular structure. This makes the print stronger and less prone to warping.

Another way to make prints stronger is through a process known as chemical dipping. This is a complex process that involves the use of caustic chemicals and should be performed by trained professionals in facilities with proper safety equipment. This technique can improve the strength of plastic, metal, and concrete prints by bonding them together with a coating that is more durable.

Designing a part for strength is essential when using 3D printing, especially for load-bearing parts. Carefully thought out CAD designs can reduce stress points by distributing loads evenly across the surface of the part. Avoid sharp corners, which concentrate stress and can lead to cracking, and reinforce critical areas with ribs and gussets. Choosing an infill pattern that maximizes mechanical strength can also be very beneficial. Examples of high-strength infill patterns include cube, gyroid, and hexagonal.

For the strongest possible printed objects, it’s important to select a quality material that is suitable for your application. 3D printing can be done with a variety of materials, ranging from elastic plastics to heat-resistant metals. A quality material will be able to withstand the required amount of pressure for your specific project, while also providing the best combination of strength and durability. For example, you may need a more flexible plastic for prototyping, while a harder plastic will be better suited for end-use products.

Customization

Customization is an important part of the 3D printing process that allows for individual creativity. This makes it ideal for producing customized products for a range of applications, from fashion where personalized jewelry pieces stand out to the automotive industry where customizable car parts are improving vehicle performance and aesthetics. It’s also transforming the medical field, where custom-made implants are providing improved patient outcomes and a more comfortable experience for patients.

Traditional manufacturing relies on standardized molds and assembly lines to churn out identical products in bulk, which limits the degree of customization that can be achieved. However, additive manufacturing eliminates the need for molds and enables manufacturers to produce items on-demand, which opens up a world of possibilities for customization at scale. In addition, the flexibility of 3D printing reduces production costs by lowering materials and assembly costs, as well as cutting down on tooling, set-up, and labor expenses.

A number of software programs are available for creating 3D designs, from basic models used in education to complex designs intended for industrial manufacturing. Some are free, while others come at a premium price. Identifying the objectives and intended purpose of the design will help users choose the best program for the job. User-friendliness, compatibility with CAD software, and plugin support are additional features to consider.

Whether designing for 3D printing or simply wanting to visualize print-outs, G-code analyzer and other free tools provide the ability to view and verify the instructions of a printed object before beginning the process. Other software, such as ideaMaker and Simplify3D, offer a more comprehensive approach, with user-friendly interfaces and advanced features that enable users to adjust specific parameters and achieve desired results.

A growing number of printers are capable of printing multiple materials, including metal. For those seeking to use 3D printers for commercial production, it’s important to work with a provider that offers a wide range of materials, from neat polymers and engineering-grade thermoplastics to more durable composite materials that can be used in end-use applications. The versatility of these materials enables manufacturers to produce more sophisticated products, reducing the time-to-market for new products and expanding their market reach.

Natural Pest Control

Pest control is a service industry with repeat business and high profit margins. Many pest control companies rely on advertising to build their customer base.

Research local businesses and compare services before selecting one. Ask for references and contact the Better Business Bureau or your state pesticide regulatory office. Click the https://facilitypestcontrol.com/ to learn more.

The goals of pest control are prevention — keeping pests from causing harm — suppression — reducing pest numbers to an acceptable level and eradication — eliminating an entire pest population.

Prevention

Preventing pests can save money and improve the quality of life. Prevention tactics include regularly inspecting facilities, identifying and reporting pest activity to your Pest Control Operator (PCO), and taking preventive measures to deter pests such as keeping buildings well-sealed and preventing waste accumulation that attracts them.

It is important to remember that pest control is a tool to be used only when the cost of controlling a pest exceeds the damage it causes. It is also essential to understand that a pest problem must be controlled at three different levels: prevention, suppression, and eradication.

Pests can cause a variety of problems in facilities such as contamination of products or destruction of equipment, and they can cause serious health issues for employees and customers. Pests such as cockroaches, rodents, fleas and mosquitoes can cause disease, while ants, beetles, flies and hornets can destroy food, produce toxic materials and irritate people’s skin.

The best way to prevent pest problems is to prevent them from entering the facility in the first place. This can be done by repairing cracks in walls, ensuring that doors and windows close tightly, using sweeps and astragals to fill gaps under and between them, and sealing wall and ceiling penetrations. In some cases, environmental controls can be used to alter the temperature, humidity and lighting conditions in storage areas to make them less desirable for pests.

If the pest is causing unacceptable harm, the next step in pest control is to suppress it at the lowest level possible. This can be achieved by using traps and baits, low-toxicity dusts and sprays, and monitoring and scouting. It is important to always read and follow the product label, particularly when applying chemical controls.

It is also advisable to tolerate beneficial insects, and to avoid killing them when possible. When this is not possible, it is important to use insecticides sparingly and to select those that are most effective at each stage of the pest’s life cycle. This will ensure that the minimum number of pesticides is used, reducing both the environmental and human risk.

Suppression

When prevention methods fail to keep pest populations below a damaging threshold and/or eradication is not possible, suppression becomes the goal. Pest suppression tactics can include cultural, mechanical and chemical controls.

Cultural Controls include practices that prevent or delay pest emergence, feeding or movement. Plowing, crop rotation, removal of weeds in greenhouses and field crops, cleaning and washing of tillage and other equipment, fungicide application at the time of planting and managing irrigation schedules to avoid long periods of high relative humidity all work to deprive pests of a favorable habitat or prevent their spread.

Biological Control involves conserving or releasing natural enemies (predators, parasitoids and/or pathogens) that prey on or kill potential pest insects. Examples include the predatory mites that suppress aphids in greenhouses, beneficial nematodes that kill harmful soil grubs and Encarsia formosa wasps that parasitize greenhouse whiteflies. The latter two are commercially available and can be mass-reared and released in greenhouses, nurseries and some fruit and vegetable fields as needed.

Augmentative Biological Control focuses on increasing the number of natural enemies present to a level that will effectively suppress a pest population. This can be done by conserving existing natural enemies, importing and releasing predators and/or parasitoids in large numbers or releasing them inundatively (i.e., overwhelming the pest population with a huge influx of biological control agents).

Chemical Controls use products to kill or inhibit pests’ growth, development and/or reproduction. These can be natural products, synthetic mimics of natural substances or traditional chemicals. When using chemicals, always read and follow product labels and NMSU guidance documents to reduce the risk of personal injury and environmental contamination. Obtain appropriate personal protective equipment (PPE), such as long-sleeved shirts, pants, close-toed shoes, gloves and face and eye protection.

Be sure to monitor and assess the success or failure of any suppression tactic, so that adjustments can be made. This information will help determine when additional or different methods of control are required, and inform future prevention and/or suppression strategies. Always consider health, the environment and economic feasibility when deciding on suppression tactics.

Eradication

Pests destroy property and crops, contaminate food, cause diseases and spread annoyance. Some, such as cockroaches, rats and dust mites, produce allergens that can trigger respiratory conditions like asthma. Others, such as termites, beetles and ants, chew wood or other structures, creating safety hazards.

Pest control is usually a combination of preventive and suppression methods. Preventive measures include keeping indoor and outdoor areas clean and free of rotting debris, sealing cracks and crevices where pests can enter, and taking out trash often to reduce odor and moisture problems. Regular cleaning of floors, countertops and storage spaces can also help deter many pests.

In addition, the use of natural enemies such as parasites, predators and pathogens can be used to control a pest population. This may be supplemented by chemical means such as releasing sterile insect males or using pheromones to disrupt mating patterns.

Eradication of a pest can be difficult and time-consuming. It requires that the pest be identified, mapped and treated, while not affecting any non-target organisms. This is known as threshold-based decision making and it is one of the most challenging aspects of eradication programs.

To eradicate a pest from an area, it must be determined how the infestation began. Observing the pest, whether it is a scurrying mouse or a dripping ant, or looking for evidence of their presence such as droppings, gnawed wood and tattered food containers, can be helpful in pinpointing the point of introduction.

A number of different diagnostic tools have been developed to aid in the detection and identification of pests. These range from simple visual inspection to DNA analysis and chemical assays. These tools need to be sufficiently sensitive and specific, as well as easy to use by non-specialists.

Integrated Pest Management (IPM) is an effective approach to pest control. This method focuses on monitoring the environment, assessing what is needed to prevent pests from entering a site, and then using a mix of physical, biological, and chemical controls to manage the pest population. This keeps the environmental impact of pesticide use low, while still managing the problem effectively.

Natural Forces

Pest control relies on a variety of natural forces — including predators, parasitoids, herbivores, pathogens, competitors and nematodes — to reduce the number or harm caused by pest insects and mites, weeds, vertebrates, fungus and other organisms. This biological control, which may be called “natural” or “organic,” can often provide more effective, less hazardous, and more sustainable pest management than chemical methods. It’s an important component of integrated pest management (IPM).

Preventing pest problems is the best option for controlling them. This includes storing foods in tightly sealed containers, regularly removing garbage, and eliminating places where pests can hide. It also involves monitoring cockroaches, termites, ants, mosquitoes and other insect pests and fungus and plant disease organisms to identify potential pests before they become a problem.

If preventive measures fail or they’re too expensive or labor-intensive, controlling pests through suppression and eradication is an option. Pests that cause unacceptable damage to crops, gardens or landscapes require pest control measures to reduce them to acceptable levels. IPM programs rely on preventive strategies, regular monitoring and record keeping to determine whether and when chemical treatments are needed, and careful use of chemicals with the least amount of risk to beneficial organisms and humans.

Suppression involves reducing pest numbers to an acceptable level using cultural, physical or mechanical controls. Altering the environment by limiting access to food, water and shelter can help reduce pest populations, as can introducing organisms that disrupt the balance between a host pest and its natural enemies. These include bacteria, nematodes, fungus and protozoa that infect or kill pests, as well as pheromones, juvenile hormones and other substances.

Predicting when a pest will reach unacceptable levels requires monitoring the population over time, which is usually done through trapping or scouting. It can be helpful to compare the pest’s population to other pest populations in a given area, or to other areas with similar environmental conditions. Temperature, moisture and other factors can influence pest potential, as can seasonal changes in pest behavior. For example, cockroaches are more active in winter, while mosquitoes are more active during summer.

The Basics of Electricity

Electricity plays a critical role in many of the world’s most important technologies. From the electric telegraph to microchips, this dynamic energy begins with electrons moving through metal wires.

Most electricity is generated at power plants using various energy sources to spin turbines that energize copper wire coils. This wire conducts electrons through closed circuits, delivering energy for homes and factories. Contact Jacksonville NC Electric now!

Electrons are subatomic particles with a negative electric charge that give rise to and interact with the electromagnetic force, one of the four fundamental forces in nature. They are a key component of conductors, and it is the interaction between these electrons and the electromagnetic force that gives rise to current flow.

Electrons move based on the relative strengths of their magnetic fields and the energy they have (in their lowest, uncharged state). This process is called “radioactivity”. The electron has an intrinsic angular momentum (spin) that has a half-integer value, defined by the Pauli exclusion principle. Electrons belong to the fermion particle family and are also referred to as leptons.

In atoms, electrons fill up certain regions of space around the nucleus, called orbitals. Each orbital is shaped differently and can accommodate only a limited number of electrons, depending on the element. Generally, the inner shells fill up before the outer ones, but it is possible for an atom to have more than one electron in its outermost shell.

The valence (outer ring) electrons are what allow an element to conduct electricity. This is because these electrons can be ejected with relatively little energy from an atom by applying an electric force to it. It is these properties of electrons that lead to the phenomena of lightning and why ancient people noticed that amber attracted small objects after it was rubbed.

Potential

The electric potential is the energy of a point charge in an electric field. It is a scalar quantity that has only magnitude and no direction; in contrast to the electric field, which is a vector quantity. It may be viewed as analogous to height: just as a released ball will fall through the difference in elevation of two points, a charged particle will move through an electric potential gradient.

In classical electrostatics, the electric potential is given by the equation (V 4pow(q, r)). The SI derived unit of electric potential is the volt (in honor of Alessandro Volta), which is also sometimes referred to as the Galvani voltage or the fermi potential, and was historically part of the centimetre-gram-second system of units.

The electric potential of a charged object depends on its position and the location of other charges, not its own charge. This is why it is possible to make a battery or other source of electricity produce different voltages at its terminals, depending on the arrangement of other components in the circuit. The potential at any point in a conductor is equal to the electric potential of the other end of the conductor if they are connected through negligible resistance wires. The potential at any other point is equal to the energy that would be needed to bring a test charge from infinity to that point against the force of gravity.

Current

The rate at which charges move past a point in a conductor is known as current. This is a physical quantity that can be measured and the unit used to measure it is called ampere, abbreviated to Amp. A current of 1 Amp represents 1 coulomb of charge passing through a cross section of wire every second.

Students will probably be familiar with metals being good conductors of electric current and with the naming convention that says when a current flows through a wire that the ends are labeled positive and negative. But this is not a perfect picture of how current flows.

In fact, a wire with current flowing through it does not necessarily have to go all the way around a circle (though it will). And in a circuit the direction of current flow can be reversed. The fact that physicists originally chose to name a wire’s positive and negative ends is somewhat arbitrary but it makes it easier for us to talk about electric current and the movement of charge carriers.

Normally the motion of free electrons in a wire is haphazard and they do not channel themselves to flow in one direction. The force that can overcome this randomness and cause current to flow is known as voltage. In the case of a battery this voltage is supplied by electrochemical reactions inside the battery cell.

Conductors

If something is a conductor, it allows electricity to flow through it. Metals are common examples of conductors. The human body is also a conductor. It offers a resistance-free route for current to travel from a power source (the electrical wire) through it to the load, which consumes the electric energy.

The electrons in conductors are loosely bound to the atoms, which means they can move easily between different atoms. Metals generally have the best electrical conductivity. They are often used for wiring. Some of them are even superconductors, meaning they have zero resistance at very low temperatures.

Most organic molecules are insulators, but some can become conductors if they’re doped with small amounts of other elements or if they contain certain impurities. Water, for example, is an insulator when pure, but it conducts well when contaminated with salt and other dissolved substances.

Electrons in a conductor can move around pretty quickly, although they don’t actually travel at the speed of light (which is about 186,000 miles per second in a vacuum). This is because the surrounding air slows their motion, and atoms themselves can experience some friction. The electrons do need a finite amount of energy to be nudged from their valence bands into their conduction bands, however. This energy is supplied by the electrical voltage or thermal effect that causes one of them to be excited.

Voltage

A voltage is the difference in electric potential between two points. It is also called electrical pressure or electric tension. It is the amount of energy needed to move a charge from one point to another through a static electric field. Voltage is not to be confused with electrochemical potential, which exists inside structures with junctions of dissimilar materials and cannot be measured directly by a voltmeter. The SI unit of voltage is the volt, named after Italian physicist Alessandro Volta, inventor of the voltaic pile, possibly the first chemical battery. 1 volt is equal to one joule of work per charge.

Most electricity is produced in power plants, where a variety of energy sources are used to spin turbine shafts. These shafts in turn turn electromagnets surrounded by heavy coils of copper wire, creating magnetic fields that cause electrons in the wire to move from atom to atom. This movement of electrons is what we call electricity, and it travels through high-power transmission lines on tall towers.

As the electricity gets closer to where it will be used, its voltage must decrease. Different kinds of transformers at utility substations do this job, boosting or “stepping down” the electricity’s voltage. The electricity is then sent through overhead or underground distribution lines to homes and businesses.

It is important to understand the relationship between current, resistance, and voltage because most electronic devices are designed to operate at specific voltages. If a device is exposed to too much voltage, it may be damaged or rendered useless. Conversely, a device operating at too low a voltage may not be able to operate properly.

Power

Students have plenty of experience using devices that rely on electric circuits for their operation (torches, mobile phones, iPods). They also likely have a sense that you need something like a battery to make them ‘work’ and that batteries can go ‘flat’.

The science behind what happens is much more complex, but it is not a mystery for students to understand when presented with the right models/metaphors/analogies. In fact, a good model/metaphor/analogy is one of the most important tools for understanding electric circuits.

Electrostatic energy is a type of potential energy that builds up on non-conductive materials, such as wool and human hair. It can be transferred to other substances by friction, and it can cause a spark when the two surfaces are touched together. It can also be converted to electrical energy in the form of alternating current by an electric generator or battery. This electrical energy can then be used by a device to do work, such as turning on a light bulb or spinning a turbine.

The electrical energy produced by a source is measured in watts, which was added to the International System of Units in 1960. Larger systems are rated in terms of kilowatts, megawatts or gigawatts. Electricity is delivered to households through overhead or underground distribution lines and arrives at homes via transformers that reduce the voltage to a safe level for use in appliances and lights.

How Proper Gutter Cleaning Protects Your Roof and Foundation

Gutter Cleaning is the process of eliminating debris like leaves and twigs from your gutter system to ensure an unobstructed flow of water into downpipes and facilitate wastewater management. Clogged gutters can stain your home’s siding and deteriorate roof shingles.

A thorough gutter cleaning should be performed on a regular basis to prevent damage and maintain the structural integrity of your home. This includes directing water away from your foundation, which can otherwise cause damage to the walls and siding of your home. Contact St. Louis Gutter Cleaning for professional help.

Keeping your gutters clear is essential to protecting your home’s foundation. Clogged gutters can cause water to build up around your home’s foundation, resulting in damage over time. This may show up as damp wall studs, basement flooding and cracks in your foundation walls. It can also lead to sagging, which can affect the structural integrity of your home.

The most common cause of clogged gutters is fallen debris from trees. Both summer storms and winter winds can deposit branches, leaves and other debris in your gutter system. This “storm shrapnel” can clog your gutters, preventing them from directing rainwater away from your house. If the water can’t be directed away from your home, it will flow over the sides of the gutters and down your walls. This erodes the soil, which can weaken your foundation walls and cause them to shift over time.

Water leaking into your home from clogged gutters can result in damage to the interior and exterior of your house, as well as mold growth and other problems. It can rot siding, drywall and carpeting, and create damp and musty areas inside the house. It can also encourage the growth of harmful mosquitoes and other pests. In the worst case, it can even rot and corrode the wood supports of your foundation.

If the water is allowed to remain near your foundation for a long period of time, it can eat away at the surrounding soil, which can cause the basement walls to crack or shift. It can also weaken the concrete that makes up your foundation, leading to a crumbling and unsteady structure.

Regular gutter cleaning helps prevent all of these problems. If you’re concerned about clogged gutters damaging your foundation, contact a professional to help with the cleanup and repair process. The first step in this process is to access your gutters and downspouts, and remove all visible debris from the gutters and downspouts. This can be done with hand rakes or power brooms, or with a ladder that’s properly positioned and secured. After you’ve removed the obvious debris, it’s time to start on the harder tasks. Start by removing the downspout cage and removing any loose spikes or hangers that are causing problems. Next, use a garden hose to wash down any remaining debris and dislodge any clogs.

Clogged Gutters Can Damage Your Roof

Clogged gutters will not only prevent rainwater from flowing away from the roof, but can also damage the fascia boards and the shingle material. Water that seeps under the shingles can cause wood rot and leaks in the attic, as well as mold and mildew inside the home.

Clogged Gutters Promote Insect Infestation

The stagnant water and organic debris in clogged gutters make them the perfect breeding ground for mosquitoes, flies, wasps, ants, mice, rats and other pests. These pests will eat the rotting wood around your house and may even enter through open windows. If left unattended, a mosquito infestation can lead to health problems for everyone in the home.

Standing water also encourages the growth of moss and other greenery. This can damage the surface of the roof and leave stains on the siding and window frames. In addition, moss can trap moisture under the shingles, leading to roof leaking and eventual structural damage.

Gutters should slope downhill to direct the flow of rainwater away from your house and toward the downspout. When this doesn’t happen, the gutters can become clogged with leaves, twigs and other debris, as well as corrode from the elements and poor installation.

Over time, the accumulated debris will weigh down your gutters and cause them to sag or pull away from the fascia boards. If this isn’t remedied in a timely manner, it could result in the gutters pulling away from the roof and falling off the house.

If you’re considering cleaning your own gutters, be sure to use proper safety equipment before climbing a ladder. Using an extension ladder or power washer without the proper safety precautions can lead to injury. It’s also important to have someone watch you from the ground, ideally from a window or patio door that can be opened quickly. You’ll need to wear eye protection while cleaning your gutters, too, as you’ll likely have to reach up high or down low to remove the debris. The best way to avoid these hazards is to hire a professional gutter cleaning service.

Clogged Gutters Can Damage Your Siding

The same debris that clogs your gutters can also damage your home’s exterior and siding. When water overflows from your gutters, it can splash down or seep into your home’s windows and frames, the siding itself, and even the wood support structure beneath your house, causing rot or mold problems. Over time, this can lead to expensive repairs or replacements.

Moreover, overflowing water can wash away mulch and other materials that protect the roots of your plants and garden. It can also wash away and destroy soil that helps stabilize your foundation, leading to cracks or shifting over time.

Clogged gutters also cause rainwater to pool around the foundation of your house, which can eventually seep into your basement or crawlspace, causing structural damage and ruining stored items. It can also damage the wood joists and columns supporting your foundation, causing them to soften or rot and resulting in costly repairs.

Dirty, wet conditions created by clogged gutters provide perfect breeding grounds for insects and pests. These include mosquitoes, rats, lizards, and spiders. The resulting mildew and mold can also trigger asthma attacks and other allergies, especially in children and the elderly.

Lastly, constant overflowing water can cause stains and streaks on your home’s exterior walls. This can be very unsightly and can affect your curb appeal.

Gutter cleaning is not a fun job to do, but it’s an important one to keep on top of. A professional can help you with the heavy-lifting, but you can also clean your own gutters if they’re not too badly clogged. Start by removing visible debris and putting it in a bucket for disposal. Then, use a gutter wand (a long attachment for your hose) or high-pressure nozzle to rinse out the remaining smaller particles.

Always wear eye protection when attempting to clean your own gutters, as there may be hidden debris lurking in places like valleys, near the chimney, and around heating, ventilation, and air conditioning (HVAC) equipment. If you don’t clean your gutters, they can become clogged again the next time it rains, and you’ll end up with an even bigger mess to deal with.

Clogged Gutters Can Damage Your Landscape

Regular gutter cleaning can prevent overflowing water from damaging your landscaping. It can also prevent soil erosion and protect plantings and vegetable gardens from washing away.

Standing water from clogged gutters can rot or erode wood and deteriorate the appearance of shingles and walls. This isn’t just a cosmetic problem, though; it can also lead to mold and mildew growth inside your home and in the surrounding shrubs and plants.

Gutters are designed to channel rainwater and snow away from your house, but if they’re clogged, this won’t happen. The water will spill over the sides of the gutters and seep into the foundation of your house, causing it to rot and weaken over time.

Rainwater can also erode the siding of your house and cause water damage to the soffits and fascia. If this continues for too long, it can cause rotting and other issues that require costly repairs.

If you have a lot of trees near your house, storms can deposit lots of debris in your gutters, including small branches and leaves. This “storm shrapnel” can clog your gutters and downspouts.

Clogged gutters can damage the walls of your house and even erode the foundation, leading to expensive repair and replacement costs. The resulting damage can also ruin the look of your home’s exterior, which can affect its value and appeal to potential buyers.

To clean your gutters, set a ladder on level ground and lean it against the wall of the house near the clogged gutter. Put on work gloves and a face mask to protect yourself from falling debris. Use a gutter scoop or trowel to scoop out leaves, twigs, dirt, and other debris from the gutter. Place this in a bucket or garbage bag as you go. When you’re done, flush out the gutters with a garden hose to remove any remaining fine particles. If you’ve successfully removed all the visible debris, check the downspout to make sure water is flowing freely. If it’s not, try using a plumbing snake to dislodge the clog. If you’re still having trouble, consider putting a nozzle on your hose and spraying it directly into the downspout to clear out the clog.